Twin Lobe Air Blower Manufacturers: Your Guide to Optimal Performance

The world of industrial machinery is vast and complex, but twin lobe air blowers stand out as a pivotal component in many operational processes. These machines are renowned for their efficiency, reliability, and adaptability across various industries. In this comprehensive guide, we will delve into the ins and outs of these machines, the prominent manufacturers, and how they align with services such as Blow Dry/Out Services at TMM.

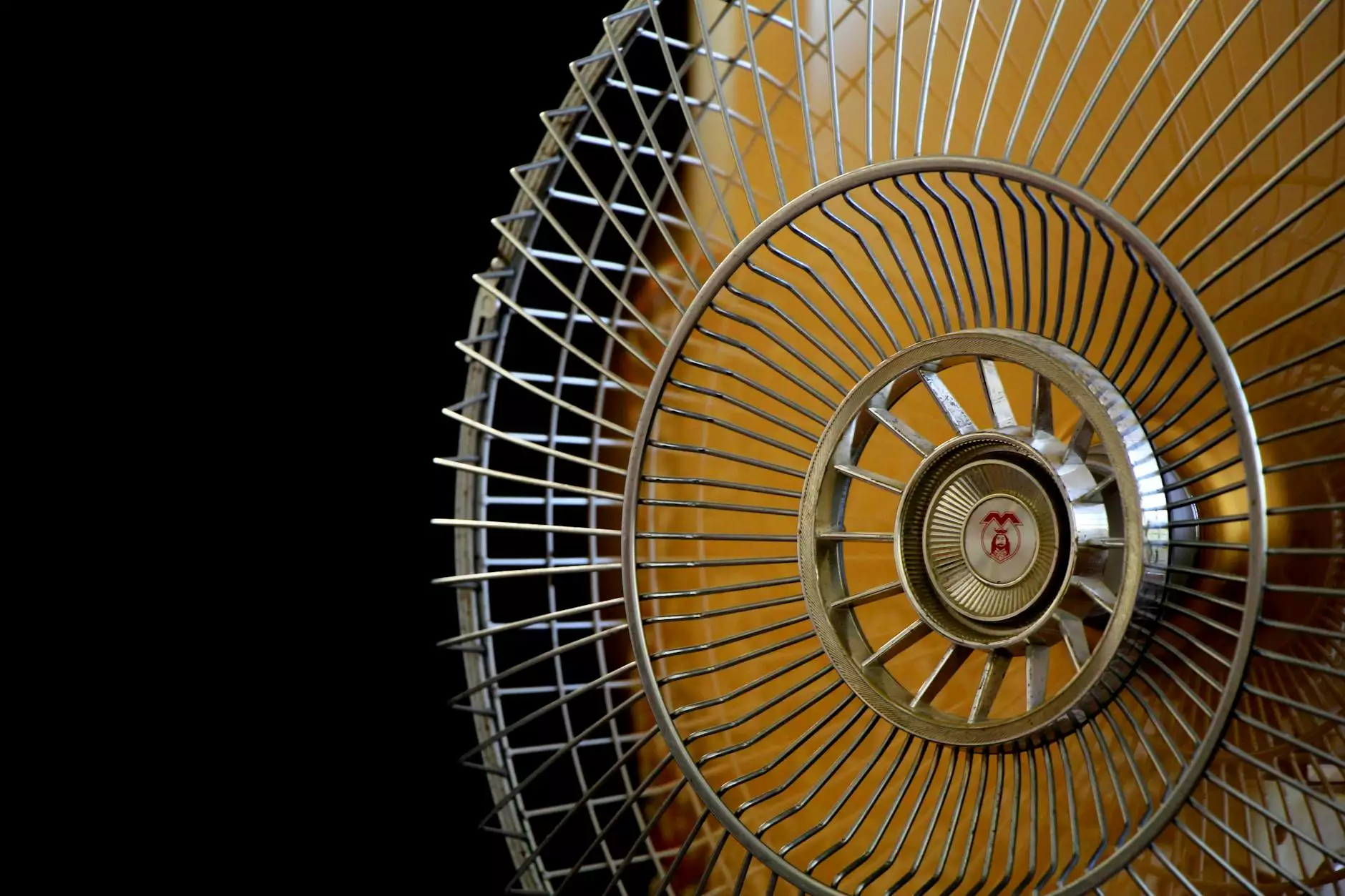

Understanding Twin Lobe Air Blowers

Twin lobe air blowers, also known as rotary lobe blowers or positive displacement blowers, are engineered to provide a consistent flow of air or gas. Their design consists of two lobes that rotate in opposition within a casing, creating a vacuum that draws air in and displaces it out at a steady rate. This operation is beneficial in various applications, including:

- Wastewater Treatment: Utilizing blowers in aeration processes.

- Pneumatic Conveying: Moving materials in bulk through pipes.

- Vacuum Applications: Providing suction for packing and handling.

- Industrial Processes: Supporting combustion and cooling in manufacturing lines.

The Importance of Quality in Manufacturing

When it comes to twin lobe air blower manufacturers, quality is of paramount importance. High-quality blowers not only enhance operational efficiency but also contribute to reduced maintenance costs and longer lifespans. Here are some critical factors that define quality in twin lobe air blower manufacturing:

1. Material Selection

The choice of materials is crucial in creating durable blowers. Manufacturers often use high-grade cast iron, steel, or aluminum, providing strength while minimizing weight. Additionally, durable coatings can protect components against corrosion and wear.

2. Precision Engineering

Precision in engineering ensures that components fit and function seamlessly. This minimizes vibrations and noise, leading to smoother operation. The refinement in the machining process also plays a vital role in the efficiency of the airflow generated.

3. Testing Standards

Reputable manufacturers conduct rigorous testing protocols to ensure their products can withstand the challenges of real-world applications. This includes endurance tests, performance validation, and compliance with industrial standards.

Top Twin Lobe Air Blower Manufacturers

Several manufacturers excel in producing twin lobe air blowers, and they often cater to specific sectors of the market. Understanding the leading players can guide companies in selecting the right partner for their blowers. Some renowned manufacturers include:

Aerzen

Aerzen is a globally recognized brand known for its innovative solutions in blower technology. Their twin lobe air blowers are celebrated for their efficiency and low operating costs, making them ideal for various industrial applications.

Roots

Roots has set a high standard in the blower manufacturing industry with their twin lobe designs. Their commitment to quality and customer service has established them as a reliable choice for many sectors.

Kaeser Compressors

Kaeser offers a diverse range of blowers, including twin lobe options. Their products are known for high efficiency and environmental sustainability, appealing particularly to industries focused on reducing their carbon footprint.

Applications of Twin Lobe Air Blowers in Blow Dry/Out Services

The Blow Dry/Out Services provided by TMM leverage the unique strengths of twin lobe air blowers to offer superior performance and reliability. Here’s how these blowers enhance these services:

1. Efficiency in Airflow

In blow dry/out services, consistency in airflow is essential. Twin lobe air blowers deliver a steady stream of air, which is crucial for effective drying processes in various industrial applications.

2. Energy Cost Savings

With their energy-efficient designs, twin lobe blowers can significantly reduce operational costs. This is particularly beneficial for large-scale operations that require extensive drying systems.

3. Versatility

TMM’s use of twin lobe air blowers allows for adaptability across different service offerings. Whether it’s drying components or materials, the versatility of these blowers makes them an invaluable asset in their operations.

Why Choose TMM for Blow Dry/Out Services?

TMM’s expertise in utilizing twin lobe air blowers for their services sets them apart in the industry. Here are several compelling reasons to partner with TMM:

Industry Experience

TMM boasts years of experience in the blow dry/out service sector. Their knowledgeable team understands the nuances of using twin lobe blowers effectively, ensuring optimal results for clients.

Customized Solutions

Understanding that every client has unique needs, TMM offers customized solutions tailored to specific applications. This personalized service helps clients achieve their goals efficiently.

Commitment to Quality

At TMM, quality is non-negotiable. The company’s commitment to leveraging top-tier twin lobe air blower manufacturers ensures that clients receive outstanding service that meets industrial standards.

Conclusion: Embracing the Future with Twin Lobe Air Blowers

In conclusion, the role of twin lobe air blower manufacturers cannot be overstated in today’s industrial landscape. Their products empower businesses, such as TMM, to deliver exceptional Blow Dry/Out Services that are efficient, cost-effective, and reliable. As industries continue to evolve, embracing innovative technology like twin lobe air blowers will be crucial for maintaining a competitive edge.

For companies looking for top-notch services, partner with TMM and harness the power of advanced twin lobe technology. Explore their offerings and discover how they can enhance your operational efficiency today!