Maximize Efficiency with a **Shrink Tube Label Maker**

In today's fast-paced business environment, efficiency and organization are critical for success. Among the various tools that businesses can utilize to streamline operations, a shrink tube label maker stands out as an essential device for a wide range of applications. This article will explore the diverse benefits of using a shrink tube label maker, highlighting how it can optimize your labeling processes, enhance productivity, and contribute to a more organized working environment.

What is a Shrink Tube Label Maker?

A shrink tube label maker is a specialized device designed for creating high-quality labels that can securely bond to various surfaces when heat is applied. Typically, the labels are printed on a thermal transfer printer, and once printed, the labels are applied to a shrink tube. When heat is applied, the tube shrinks, conforming tightly around the printed label and the object it is attached to, ensuring a durable and long-lasting display.

Key Components of a Shrink Tube Label Maker

- Printer: The core component that produces high-resolution labels, often utilizing thermal transfer technology.

- Shrink Tubing: Plastic tubing that shrinks upon heating, providing a secure fit around the label and object.

- Cutting Mechanism: Ensures precise cutting of the labels to the desired size.

- Software Interface: An easy-to-use software that allows for custom label design, including fonts, sizes, and graphics.

Why Invest in a Shrink Tube Label Maker?

Investing in a shrink tube label maker can provide numerous advantages for businesses across various sectors, from electronics manufacturing to printing services. Here are several compelling reasons to consider this investment:

1. Enhanced Durability and Longevity

Labels created using a shrink tube label maker are known for their durability. When heat is applied, the tubing provides a tight seal that protects the label from wear and tear, moisture, and environmental factors. This is particularly important for industries such as electronics, where labels need to withstand exposure to various elements without fading or wearing away.

2. Improved Organization

Having clear and durable labels enhances organization within any workspace. Utilizing a shrink tube label maker allows for the categorization of products, equipment, and inventory systematically. This not only makes it easier to find items but also aids in inventory management. An organized workspace leads to improved productivity, as employees can spend less time searching for items and more time focused on their tasks.

3. Professional Appearance

When you apply a shrink tube label, it presents a professional image to clients and customers. Labels produced using a shrink tube label maker are clean, consistent, and visually appealing. This professionalism can contribute to your brand's overall perception, making it more trustworthy and reputable in the eyes of customers.

4. Customizability

With a shrink tube label maker, businesses can create custom labels tailored to their specific needs. The software that accompanies these machines allows for diverse formatting options, including the use of logos, barcodes, and various fonts. This level of customizability aids in branding efforts and can significantly enhance product recognition in the market.

5. Cost-Effectiveness

While there is an upfront investment for a shrink tube label maker, the long-term benefits outweigh the costs. Printing labels in-house eliminates the need to outsource labeling tasks, resulting in significant savings over time. Additionally, businesses can optimize label production for specific campaigns or product launches without incurring additional fees.

Applications of a Shrink Tube Label Maker

From the electronics industry to general printing services, the applications of a shrink tube label maker are vast and varied. Below are some common applications where this tool proves invaluable.

1. Industrial Labels

In manufacturing settings, equipment and machinery are often labeled for safety and operational efficiency. A shrink tube label maker allows for the creation of durable labels that withstand harsh conditions, ensuring that important information remains visible for the lifespan of the equipment.

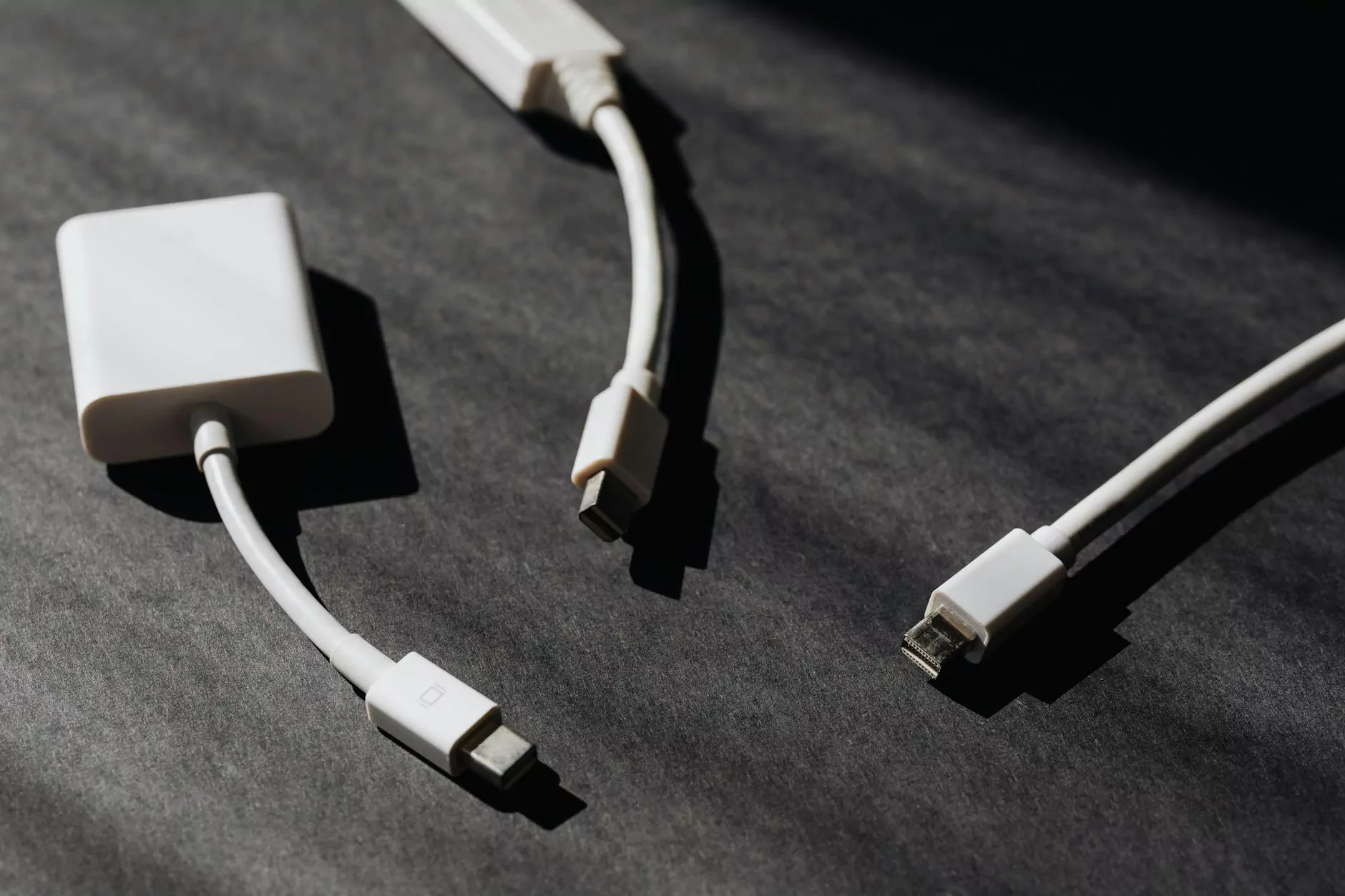

2. Cable Management

For businesses dealing with wiring and cabling, proper labeling is essential for organization and safety. A shrink tube label maker can effectively label cables, making it easier to identify wires during installation, maintenance, or troubleshooting.

3. Product Labeling

Retailers and manufacturers need flawless product labeling for branding and compliance purposes. Shrink tube labels can feature product information, barcodes, and marketing materials securely attached to the product for a professional finish.

4. Asset Tracking

Tracking assets within a business is crucial for accountability and management. Utilizing a shrink tube label maker allows businesses to print and attach labels to valuable equipment and inventory, facilitating easier tracking and audits.

Choosing the Right Shrink Tube Label Maker

When selecting a shrink tube label maker, several factors should be considered to ensure you choose the right model for your business needs.

1. Printing Technology

Consider the printing technology used in the label maker. Thermal transfer printers are often preferred for their ability to produce high-quality, long-lasting labels quickly. Look for models that offer various printing resolutions to meet your specific requirements.

2. Software Compatibility

Ensure that the label maker's software is user-friendly and compatible with your existing systems. The ability to easily design and customize labels will significantly enhance your productivity.

3. Label Compatibility

Different models may support various sizes and types of shrink tubing. Check for compatibility with the materials you plan to use to avoid issues during label production.

4. Cost and Support

Consider the total cost of ownership, including initial investment, supplies, and maintenance. Additionally, assess the manufacturer's customer support and warranty options, as a reliable support system can provide peace of mind.

Integrating the Shrink Tube Label Maker into Your Business

Integrating a shrink tube label maker into your business operations can be seamless, provided you follow specific best practices:

1. Train Your Team

Invest time in training employees on how to use the label maker effectively. Proper training will enhance productivity and ensure that labeling tasks are performed accurately.

2. Standardize Labeling Processes

Create standard operating procedures (SOPs) for labeling processes. This ensures consistency and quality in all labels produced, thereby maintaining professional standards.

3. Maintain Equipment Regularly

Regular maintenance of the label maker is essential for longevity and optimal performance. Follow the manufacturer's guidelines for cleaning and servicing the equipment.

Conclusion

In conclusion, a shrink tube label maker is an invaluable asset for any business looking to enhance efficiency and organization. With the ability to produce durable, customizable labels, this device accommodates various applications across different industries. By investing in a shrink tube label maker, businesses can improve organization, reduce costs, and present a professional image to customers. The right model can transform your labeling processes, making them more efficient and reliable, ultimately contributing to your overall success.